Lean Project Management Dashboard

What is Lean Project Management?

Lean project management is a type of project management that is based on the principles of lean manufacturing. Lean manufacturing is a type of manufacturing that is focused on eliminating waste in all aspects of the manufacturing process. The goal of lean manufacturing is to create more value for the customer while using fewer resources.

Lean manufacturing principles can be applied to any type of organization, not just manufacturing. Lean project management is a type of project management that is based on the principles of lean manufacturing. Lean project management aims to create more value for the customer while using fewer resources.

There are many benefits of lean project management. Some of the benefits include shorter project timelines, reduced costs, improved quality, and increased customer satisfaction.

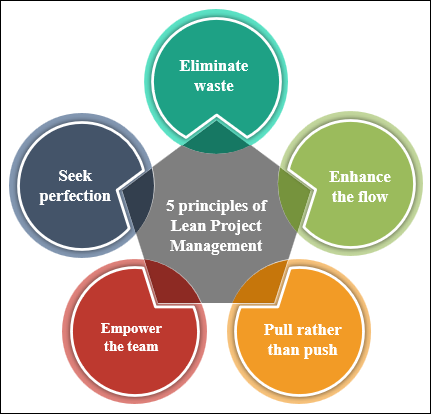

5 Principles of Lean Project Management

The 5 Principles of Lean Project Management are:

- Eliminate waste

- Enhance the flow

- Pull rather than push

- Empower the team

- Seek perfection

Each of these principles is important, but when combined they provide a powerful framework for Lean project management.

- Eliminate Waste: One of the key principles of Lean is to eliminate waste. This means identifying and removing anything in the project that does not add value.

- Enhance Flow: Another key principle of Lean is to enhance flow. This means creating a smooth and uninterrupted flow of work, from start to finish.

- Pull Rather Than Push: The third principle of Lean is to pull rather than push. This means that work is pulled through the project, rather than being pushed.

- Empower the Team: The fourth principle of Lean is to empower the team. This means giving team members the authority and responsibility to make decisions and act.

- Seek Perfection: The fifth and final principle of Lean is to seek perfection. This means continuously striving to improve the project, to achieve perfection.

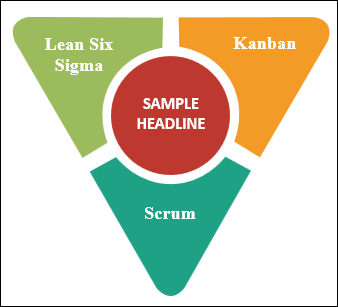

What are the Types of Lean Project Management?

Lean project management is a type of project management that is focused on maximizing efficiency and eliminating waste. The goal of lean project management is to create value for the customer by delivering the project as quickly and efficiently as possible.

There are Three Types of Lean Project Management: Lean Six Sigma, Kanban, and Scrum.

Lean Six Sigma is a methodology that is focused on improving quality and efficiency by identifying and removing waste and reducing variation.

Kanban is a system that is focused on optimizing's workflows by visualizing work and limiting work in progress.

Scrum is an agile methodology that is focused on delivering projects in a short, iterative fashion.

Each of these methods has its strengths and weaknesses, and there is no one right answer for every project. The best way to determine which type of lean project management is right for your project is to experiment and see what works best for you and your team.

Explain in Detail Implementing Lean Project Management?

Implementing lean project management can help you to optimize your resources and get the most out of your team. It is a process that is based on the principles of lean manufacturing, which is a methodology that is used to streamline production and minimize waste.

You need to take a few key steps to implement lean project management success. First, you need to identify the value stream. This is the series of activities that are necessary to complete a project from start to finish.

Next, you need to identify the sources of waste in the value stream. This can be anything from inefficient processes to wasted materials. Once you have identified the sources of waste, you can then start to implement changes to eliminate them.

By following these steps, you can start to implement lean project management in your own projects and see amazing results!

When Should You use Lean Project Management?

The first step in deciding when to use lean project management is understanding what it is and what its benefits are. Lean project management is a methodology that eliminates waste and ensures that value is delivered to the customer as efficiently as possible.

Many different benefits can be achieved by using lean project management, such as reduced costs, shorter project timelines, and improved quality.

It is important to note that lean project management is not a one-size-fits-all solution – it should be customized to fit the specific needs of the project. To decide when to use lean project management, you must first understand your project and its objectives.

Once you have a good understanding of lean project management and its benefits, you can then start to assess when it would be most beneficial to use this methodology on your own project.

Benefits of Lean Project Management?

Lean project management is a term used to describe a project management philosophy that is focused on continuous improvement, waste reduction, and customer value. The goal of lean project management is to deliver the maximum value to the customer while minimizing waste and maximizing efficiency.

Some of the Benefits of Lean Project Management Include:

- Improved Quality: Lean project management emphasizes continuous improvement, which leads to higher-quality products and services.

- Increased Efficiency: Lean project management strives to minimize waste and maximize efficiency, which leads to increased productivity and lowers costs.

- Improved Customer Satisfaction: By delivering the maximum value to the customer, lean project management leads to improved customer satisfaction.

- Increased Agility: Lean project management is focused on continuous improvement, which makes organizations more agile and responsive to change.

- Improved Competitiveness: The benefits of lean project management help organizations to better compete in the marketplace.